Plastic Extrusions Portfolio Gallery

Feel free to view the variety of products that we have provided clients covering a multitude of industries. If you have questions about production, or need more detail about a specific product, call us at 877-439-4896.

At Plastic Extrusion Technologies, innovation and precision converge to shape a future of plastic extrusions that transcend traditional boundaries. With over a century of expertise, we take pride in delivering cutting-edge solutions that cater to a diverse spectrum of needs. Whether you’re exploring safety components, acrylic signage, or seeking custom extrusions, our expansive portfolio is designed to meet the highest standards of quality and versatility.

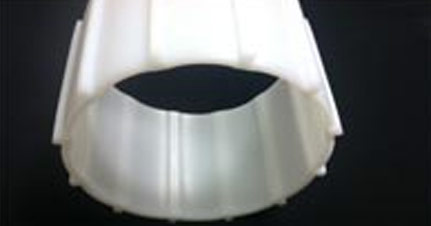

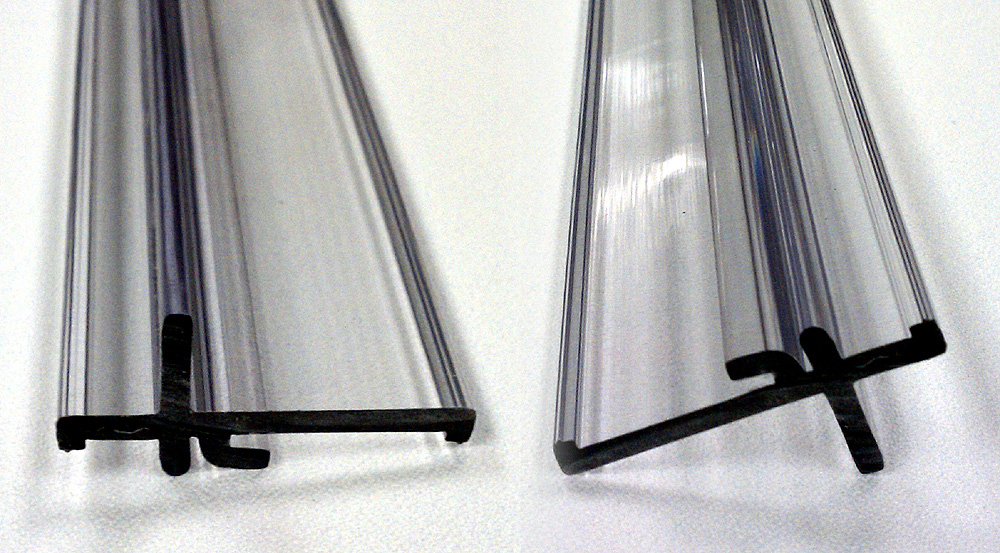

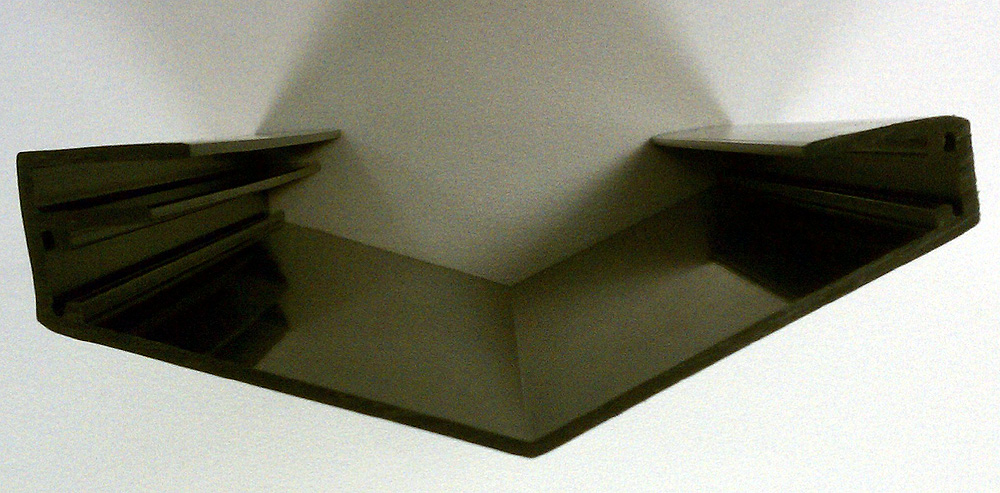

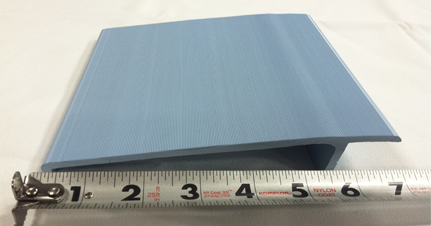

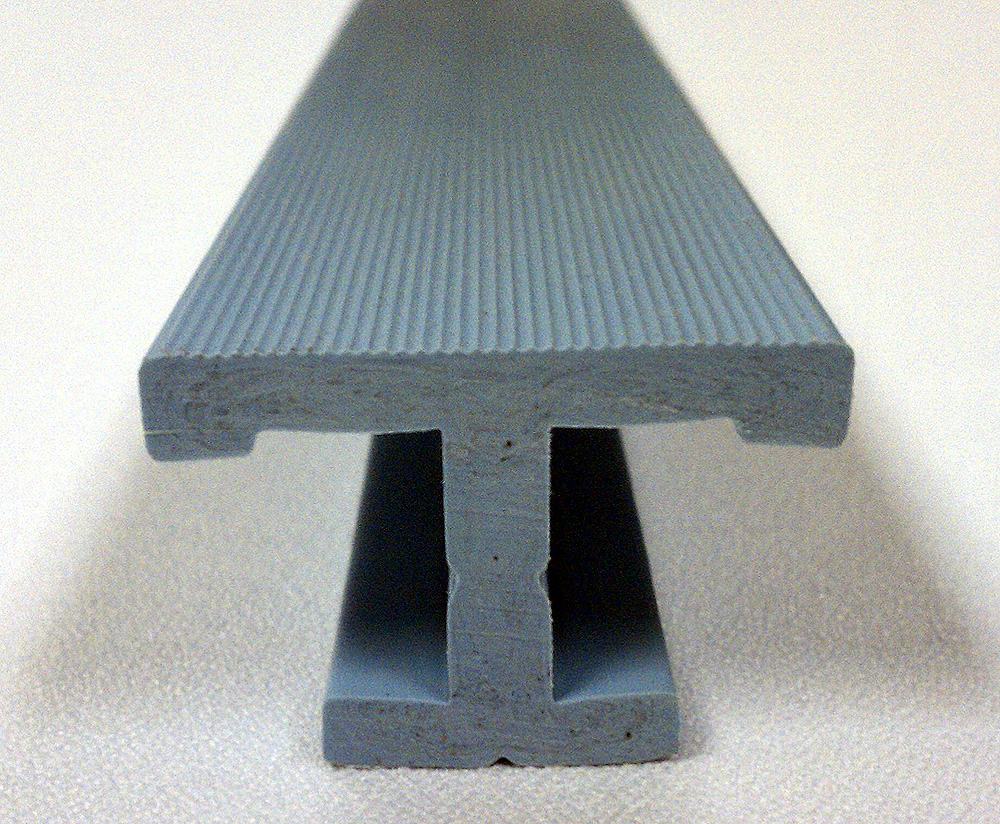

Plastic extrusion, a cutting-edge manufacturing process, forms the backbone of our operations. We specialize in creating custom extrusions that defy traditional limits, with a focus on safety, durability, and versatility. Our commitment to excellence is evident in the meticulous crafting of products such as the 7 Inch Tube, 8 Inch Polyethylene Tube, ABS Profiles, and more. The plastic extrusion process, a symphony of melting, shaping, and cooling, enables us to produce unique profiles catering to diverse applications.

FAQ:

What is ABS material?

ABS stands for Acrylonitrile Butadiene Styrene, a versatile thermoplastic polymer known for its strength, impact resistance, and excellent molding qualities. It is widely used in various industries, including the production of safety equipment and custom extrusions.

What is ABS plastic?

ABS plastic is a polymer composed of three monomers: acrylonitrile, butadiene, and styrene. Known for its durability and versatility, ABS plastic is commonly used in manufacturing a wide range of products, including safety equipment, profiles, and signage.

Can ABS material be extruded?

Yes, ABS material can be extruded using advanced plastic extrusion technology. Plastic Extrusion Technologies specializes in producing ABS profiles, including safety components, through the extrusion process, offering custom solutions tailored to your specific requirements.

What is extruded polyethylene?

Extruded polyethylene refers to the process of shaping polyethylene material by forcing it through a die. Our portfolio includes a variety of polyethylene products, such as the 7 Inch Tube and 8 Inch Polyethylene Tube, showcasing the versatility and durability of extruded polyethylene in different applications.

Where can I find co-extruded polyethylene products?

Our product range includes co-extruded polyethylene profiles like the Co-Extrude Interlocking Profile Co-extrusion combines multiple materials to achieve specific properties, enhancing the functionality and performance of the final product.

What safety products does Plastic Extrusion Technologies offer?

Our safety products include the 7 Inch Tube, Safety Rack, and various profiles designed for safety applications. These products are crafted with precision and attention to detail to meet the highest safety standards.

How does the plastic extrusion process work?

The plastic extrusion process involves feeding thermoplastic resin into an extruder, melting the material, shaping it through a die, cooling, and finalizing the product. Our advanced extrusion machines and skilled team ensure the highest quality throughout the process.

Are recycled materials used in plastic extrusions?

Yes, recycled plastics can be incorporated into the extrusion process, promoting sustainability. Plastic Extrusion Technologies is committed to environmentally friendly practices, and we can discuss incorporating recycled materials into your custom extruded products.

Why choose ABS material for extrusions?

ABS material is chosen for extrusions due to its exceptional strength, impact resistance, and molding qualities. Discover the versatility of ABS in creating durable profiles and safety components tailored to diverse industry needs.

Can you elaborate on the characteristics that make ABS plastic suitable for safety equipment?

ABS plastic’s composition, including acrylonitrile, butadiene, and styrene, contributes to its outstanding durability and impact resistance, making it an ideal choice for safety equipment. Its unique blend of properties ensures that safety components crafted from ABS material provide reliable protection in various applications.

In what applications is the use of plastics ABS most prevalent?

Plastics ABS find widespread use across diverse industries, including safety equipment and custom extrusions. Its versatility makes it a go-to material for manufacturing profiles, signage, and other products, meeting the specific requirements of applications ranging from safety gear to custom-designed extruded components.

How does the composition of ABS plastic contribute to its molding qualities?

ABS plastic’s composition, combining acrylonitrile, butadiene, and styrene, contributes to its excellent molding qualities. This unique blend allows for intricate shaping and precise detailing, making ABS a versatile material for molding applications in manufacturing a wide range of products.

At Plastic Extrusion Technologies, we don’t just offer products; we provide solutions tailored to your unique requirements. Contact us for more information about our ABS profiles, safety products, or the plastic extrusion process. Request a quote and experience the excellence of our plastic extrusion capabilities, where innovation and precision converge to shape the future of plastic extrusions.