Our Capabilities

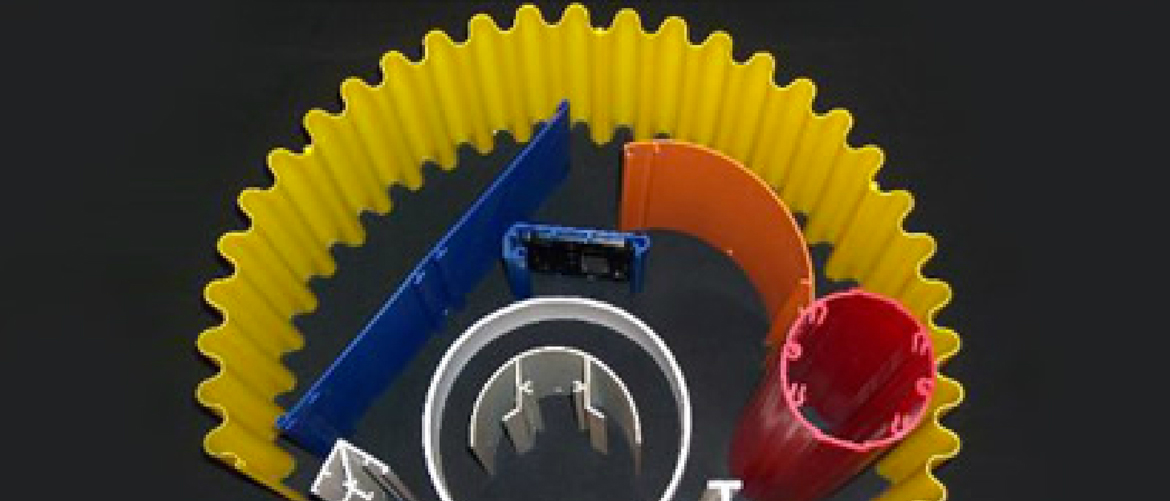

Custom plastic manufacturing is the backbone of Plastic Extrusion Technologies. We work diligently with our clients to provide unique custom plastic profiles, designs, and solutions to fit each customer’s needs. Our plastic products include rigid and flexible PVC, polyethylene, polystyrene, polypropylene, acrylic, PC/ABS, Polycarbonate, Noryl, and T.P.R. Each product and service we offer is dedicated to ensuring your complete satisfaction through our unique and diverse materials, colors, shapes, and sizes.

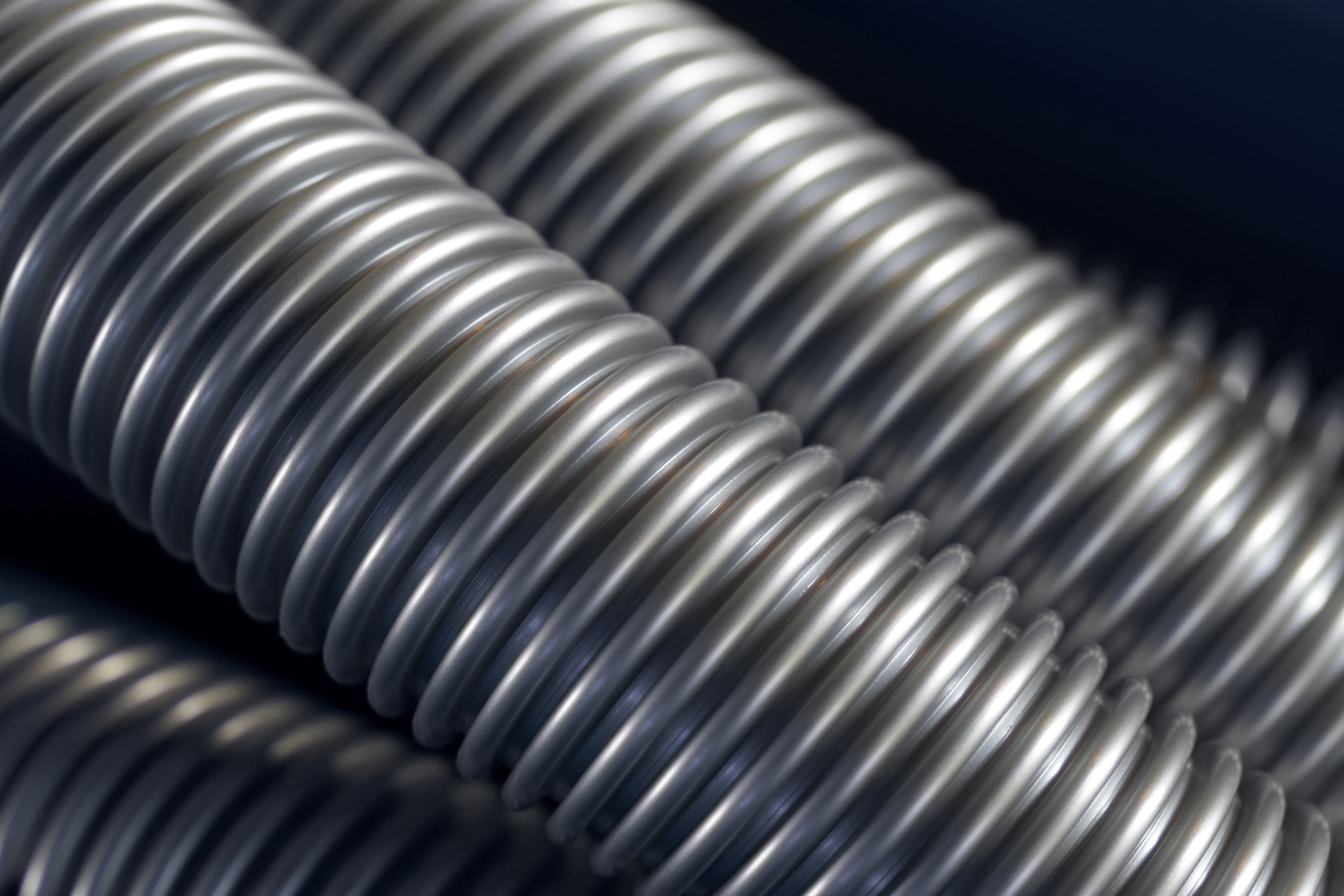

Our plastic extrusion process involves feeding high-quality thermoplastic and other raw materials through a tooling extruder to create custom extrusion products specifically designed for you. The process can take many forms, including single extrusion, tubing extrusion, and co-extrusion.

Below is a sampling of some of Plastic Extrusion Technologies capabilities:

With over 100 years of experience in plastic manufacturing and extrusion services, P.E.T. can provide you with the highest-quality, helpful products that hold long-lasting tolerances. Contact us today for more information about our custom plastic manufacturing process, or request a quote. We look forward to earning your trust and becoming your top extrusion manufacturer!