Plastic Extrusions

HIGH-QUALITY RESINS

FAST PRODUCTION/DELIVERY TIMES

45,000 SQ. FT. FACILITY

STATE-OF-ART MACHINERY

100+ YEARS OF EXPERIENCE

AGGRESSIVE PRICING

Custom Plastic Extrusions for Every Application

Plastic Extrusion Technologies is an Ohio-based manufacturer that can meet all your custom plastic profiles and plastic tubing extrusion throughout the United States. We manufacture everything, from point of purchase signage to standard plastic profiles in our Midwest facility.

Plastic Extrusion stands out in the realm of plastics manufacturing, offering unique advantages for our customers. Extrusion is a versatile technique accommodating a vast spectrum of plastic materials. Unlike traditional plastic injection molding, extrusion can continuously shape molten plastic to desired specifications, offering large-scale production quickly.

Our Plastic Extrusion Process

Utilizing plastic extrusion technology requires a symphony of skills. At its core, the extrusion process seems straightforward, but it demands precision and know-how. To craft custom plastic extrusion products, companies like Plastic Extrusion Tech use an advanced plastic extrusion machine and skilled technicians.

How P.E.T. transforms commodity plastics into tangible plastic parts:

1. Feeding: The plastic extruder, a single or twin-screw extruder, takes in thermoplastic resin. Resins, either beads or pellets, can include materials like low-density polyethylene or thermoplastic elastomer.

2. Melting: As the polymer resin enters the extrusion line, it is heated into a polymer melt. This allows shaping of the extrusion.

3. Shaping: The molten plastic then is forced through a die, functioning as a mold. A breaker plate ensures an even flow before it reaches the die. This stage dictates the final shape of the plastic extrusion (plastic film, plastic sheet, tubing).

4. Cooling & Finalizing: Post extrusion, cooling rolls stabilize the freshly shaped material. Thereafter, it’s cut, prepared, or 3D printed based on the requisite specifications.

With Plastic Extrusion Tech’s advanced extrusion machinery and expertise, the output potential is limitless. From wire insulation and stock plastic extrusions to unique tooling for plastic parts, our extrusion line exemplifies the best of custom plastic extrusion work. Notably, we’re not confined to “just” plastic extrusions; our capabilities extend to aluminum extrusion as well.

P.E.T.’s plastic extrusion process is wide and varied and can produce many different forms, including:

Being the most common type of plastic extrusion in the industry, single extrusion profiles are designed using a single thermoplastic material cut to varying lengths. Plastic Extrusion Technologies has the capability to produce a wide gamut of profiles, from very simple to very complex. We also offer secondary processes such as Notching and Drilling, Plastic Gluing and Taping, Punching, Forming, and Heat Welding.

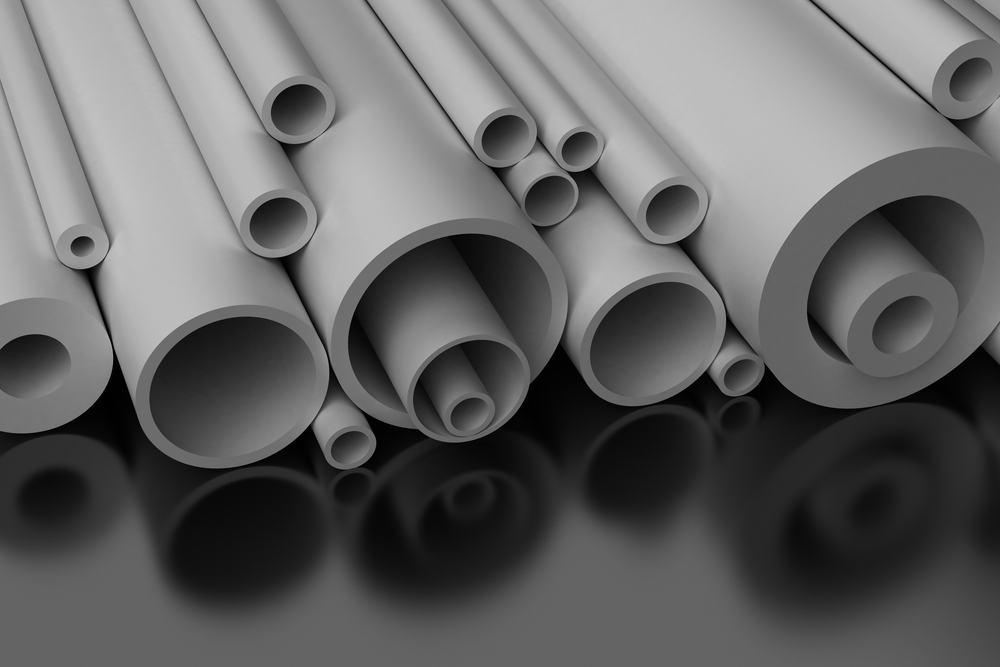

Our state-of-the-art plastic tubing extrusion processes allow us to hold to industry-challenging tolerances and manufacture extrusions using a broad range of thermoplastic materials. We will meet your exact specifications and exceed your highest expectations. P.E.T. is committed to the strictest quality standards, ongoing investment in the latest equipment, and incomparable client service.

Coextrusion options are also available. This type of custom plastic extrusion utilizes two or more extruders to melt and deliver a steady volumetric throughput of different viscous plastics to a single extrusion head (die), which extrudes the materials into the desired form. The thickness of each layer is determined by the relative speed and size of the individual extruders delivering the materials.

Materials We Use

Rigid PVC – strong, low-cost plastic material that is extremely easy to fabricate.

Polyethylene – lightweight, durable thermoplastic with variable crystalline structure.

High Impact Polystyrene (HIPS) –versatile thermoplastic known for high impact resistance and processing ease.

Polypropylene – a thermoplastic polymer.

Polyurethane – polymer composed of organic units connected by urethane links.

Acrylic – petroleum-based thermoplastics with high optical clarity that can be manufactured into custom shapes and sizes.

Polycarbonate – thermoplastic polymers containing carbonate groups.

Flexible PVC – soft plastic material ranging from transparent to opaque.

Noryl – non-reinforced blend of polyphenylene ether and high-impact polystyrene.

TPR – modified from Styrene-butadiene-styrene Block Copolymer (SBS).

ABS – impact-resistant engineering thermoplastic & amorphous polymer.

Plastic Extrusions Portfolio Gallery

Fluted Tube, Rigid PVC

These tubes were used as covers for parking meter poles to provide protection from the weather. These keep expensive parking meters protected from the elements.

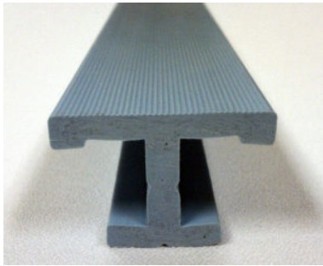

Ribbed Handle, Rigid PVC

This product was part of a squeegee application. These ribbed handles can be used to clean car windows and be placed on cleaning tools to clean water from windows and floors.

Plastic Extrusions Frame, Rigid PVC

Plastic Extrusion Technologies manufactured this rigid PVC frame for a client based in New Jersey. These frames were used to provide a structure for a point of purchase product display for stability.

Interlocking Profile, Rigid PVC

Plastic Extrusion Technologies provided a rigid PVC interlocking profile for a client in New York. This profile was used for a commercial product application.

Pedestal, Rigid PVC

Plastic Extrusion Technologies provided rigid PVC pedestals for a New Hampshire client. This product was for a commercial product application.

Flared Handle, Rigid PVC

PVC is one of the most popular plastics, used heavily in the packaging industry because if its light weight and durability.

Custom Extruded Plastic Profiles

Our extruded profiles produce custom shapes to meet your specifications, and our multi-line operation allows for the easy production of small to large plastic profiles ranging from 1/32” to 13”. With our ability to create profiles of infinite length in large or small production volumes, mass production is never an issue at P.E.T.

Plastic Extrusion Technologies can produce customized profiles, from the simple to the complex, with our engineering expertise. We also offer secondary processes such as plastic Notching and Drilling, Gluing and Taping, Punching, Forming, and Heat Welding.

We are confident that Plastic Extrusion Technologies will be the best manufacturing partner for you, and believe you’ll feel the same. We work with your current plastic extrusion tooling, or purchase new machinery for long-term engagements to provide high-quality extruded products. Our cost-effective manufacturing process is ideal for both custom extruding and high-volume plastic extrusions.

Your Competitive Edge in Plastic Extrusions – P.E.T.

Fresh pricing on plastic extrusion products

High quality resins and manufacturing processes

Speedy delivery times

Insights and expertise on your current designs and ideas

With over 45,000 square feet of production space, our plastic extrusion facility is equipped with state-of-the-art machinery and a skilled team that uses it. We have over 100 years of experience in the plastics industry, and the ability to produce plastic profiles of limitless length in both vast and minimal production volumes. Plastic Extrusion Technologies has the experience, technology and knowledge to assist you in the design, production and finishing of your extruded plastic profiles and plastic tubing products. Please contact us below to get started with P.E.T!