Plastic products take many different forms, but they all start as raw material. During the plastic extrusion process, resin beads are melted down, filtered, pushed through a die, and then cooled. This high-volume manufacturing process includes the following steps.

- Raw plastic (raw material) is fed into a hopper with colorants, additives, and UV inhibitors that are required for that particular job. It is fed down into the extruder while it awaits the next step in the manufacturing process.

- The plastic beads or granules flow from the hopper down into the feed throat. They are dispensed onto a large spinning screw extruder.

- The beads move from the rotating screw while being heated to the melting temperature for that type of plastic. The plastic is now mixed and has a thick consistency after it is heated up.

- The molten plastic flows across a breaker plate and screen. The screen removes any contaminants or inconsistencies, the breaker plate changes the motion of the plastic materials from rotational to longitudinal.

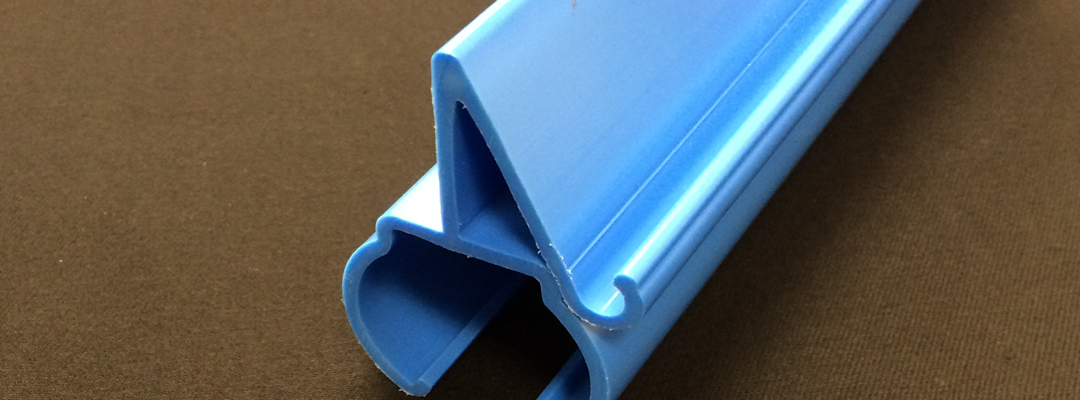

- The final stage of the finished product is being put into a die. The plastic flows smoothly from the cylindrical profile of the extruder into the final shape. Consistency in this flow is critical to achieving the desired final product.

Plastic Extrusion Technologies creates high quality objects using thermoplastic material in order to protect against corrosion over time. Some of our most plastic products that we have the capabilities to create include, but are not limited to HVAC, cable, wire insulation, weather stripping, and refrigeration applications.

- Brush products

- Refrigeration

- HVAC

- Cable and wire

- Safety products

- Point of purchase displays

- Commercial construction

-

Agriculture

-

Transportation

-

Safety

-

Hydroponics

Contact Plastic Extrusion Technologies

As one of the top plastic extruders in Ohio, Plastic Extrusion Technologies provides quality plastic extrusions, tubing extrusions, and injection molding. We are always eager to find cost-effective solutions to your polymers and plastic extrusion needs. We are here to solve any extrusion challenge you might run into by providing the highest quality extruded parts on the market.

If you require plastic extruding services, contact Plastic Extrusion Technologies for more information. With over 100 years’ experience in the plastic industry, we would be happy to answer any questions you might have about plastic materials and extruded products. Contact us today for more information about our plastic extrusion capabilities and manufacturing process, or feel free to request a quote.