Extruded Acrylic

We specialize in providing high-quality, custom extruded acrylic products, including sheets, tubes, and profiles. Known for their strength, clarity, and versatility, our acrylic extrusions serve a variety of industries and applications.

Why Choose PET for Your Acrylic Extrusions?

With over one hundred years of combined experience in plastic extrusion, we offer precision, consistency, and flexibility in every acrylic product we produce.

Our team is dedicated to meeting your project’s exact requirements, from custom dimensions to secondary finishing options, ensuring every piece delivers reliable performance and exceptional quality.

Our Unique Capabilities

Leveraging advanced extrusion and fabrication processes, we deliver custom acrylic solutions designed to meet the most demanding specifications and projects.

Custom Fabrication

Our extruded acrylic is available in a variety of colors, shapes, and sizes. We work closely with you to ensure every product meets your specifications, whether you need acrylic sheets, tubes, or specialized profiles.

We have the equipment and experience to ensure accuracy and quality in every piece of acrylic we produce. Our team utilizes the following fabrication methods:

- Cutting and Machining: CNC routers and laser cutters enable precision cutting, ideal for detailed custom profiles.

- Thermoforming and Bending: Heated acrylic can be shaped for applications like machine guards, covers, and enclosures.

- Bonding and Assembly: Solvent welding creates strong, impermeable joints for display cases, aquariums, and other multi-component assemblies.

- Polishing and Finishing: Flame and abrasive polishing enhance the clarity of edges, ensuring a clean, professional appearance.

Advanced Extrusion Technology

Producing over 7 million pounds of plastic material per year, we handle both large and small quantities per your specifications.

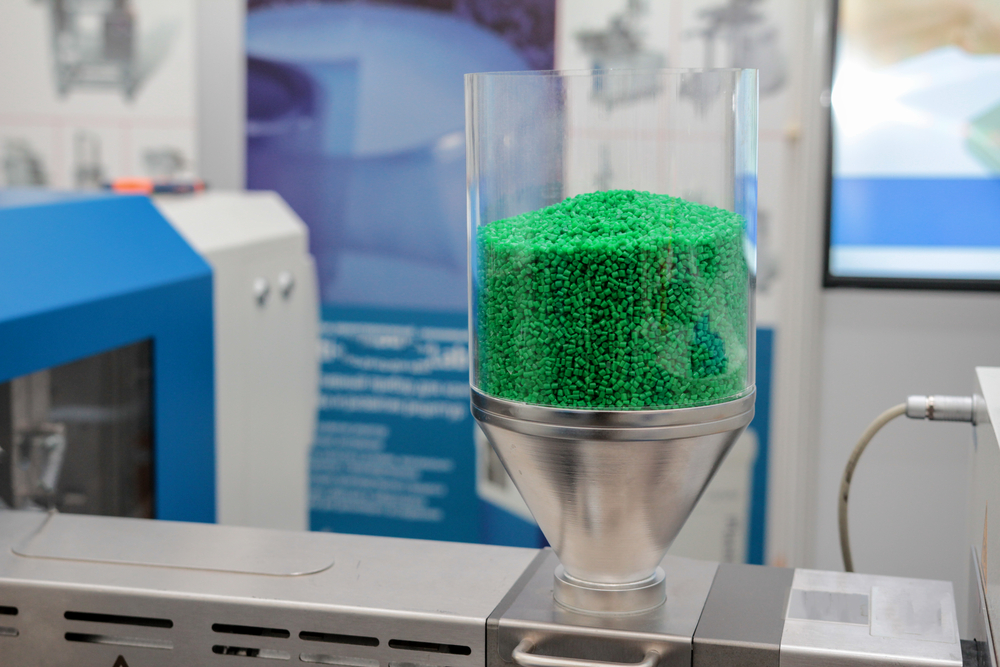

Using a continuous extrusion process, we produce acrylic with consistent thickness, uniform clarity, and durability, ensuring cost-effectiveness without sacrificing quality. Our plastic extrusion processes take many forms, including:

- Single Extrusion

- Coextrusion

- Tubing Extrusion

- Standard & Custom Extruded Profiles

We can extrude acrylic up to an 18” width, and in some cases, even wider. We can also run lengths of 24’.

Acrylic Material Options

High Optical Clarity: Our extruded acrylic offers excellent light transmission, ideal for applications requiring clear visibility, such as signage, displays, and protective screens.

Custom Shapes and Sizes: Our extrusion capabilities allow for various acrylic profiles, including sheets, tubes, and complex custom shapes. We can meet your exact needs, down to the most minute specificity.

UV and Weather Resistant: Designed for durability, our extruded acrylic products are resistant to yellowing and UV degradation, making them suitable for both indoor and outdoor applications.

Color Options: Beyond transparent acrylic, we provide custom color matching to align with branding or specific project requirements, enhancing both function and aesthetic appeal.

The Advantage of Our Extruded Acrylic Products

Economical and Efficient: The continuous extrusion process enables high-volume production, reducing material costs and offering a more affordable alternative to glass and cast acrylic.

Lightweight Yet Durable: At half the weight of glass, extruded acrylic is easy to handle, transport, and install while providing excellent impact resistance.

Easy Fabrication and Finishing: PET’s extruded acrylic supports a variety of fabrication methods, from cutting and machining to bending and bonding, providing versatility for custom shapes and finishes.

Extruded Acrylic Applications

Protective Screens and Barriers: A safer, shatter-resistant alternative to glass, our extruded acrylic screens offer clarity and durability for protective barriers, including partitions and safety shields.

Signage and Displays: With its superior light transmission, extruded acrylic is ideal for illuminated signage and displays, creating vibrant visuals for retail and corporate environments.

Glazing and Skylights: Weather-resistant and UV-stable, PET’s acrylic extrusions serve as a reliable solution for skylights, windows, and other glazing applications that need long-term clarity and durability.

Partner with PET for Custom Extruded Acrylic Solutions

With over a century of combined expertise in plastic extrusion, we are committed to providing products that meet stringent standards of quality, durability, and performance.

Our team has both the expertise and the resources to bring your vision to life. From initial consultation through final delivery, our team works alongside you to deliver solutions that optimize your projects, enhance your operations, and support your business goals.