Plastic extrusion starts with tiny plastic pellets, which are mixed with the required additives and colorants for the final product. These pellets may be polyethylene, polypropylene, PVC, ABS, Acrylic, Noryl, or a polymer blend like a thermoplastic material, or a polycarbonate composite, depending on the customer’s needs. The plastic pellets are then gravity fed from the hopper down into a feed throat, and onto a rotating screw extruder, which evenly distributes them as they are heated to that polymer’s melting point. Extrusions may also be made with twin screw extruders, rather than single screw extruders, in order to decrease energy consumption and increase production speeds.

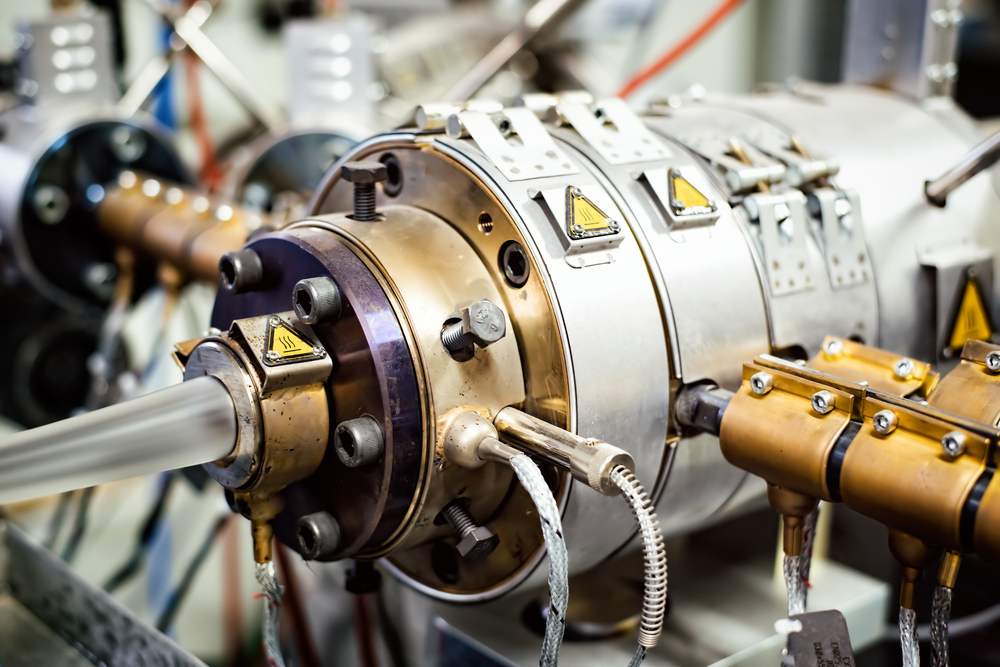

At the end of the barrel of the machine is a breaker plate and a screen. The molten plastic material flows across the breaker plate to change the flow of the plastic material to longitudinal, rather than rotational, and then it is pushed through the screen to remove any granules of contaminants that might compromise the quality of the final product. The final step of the process is the extrusion itself, where the molten plastic is pushed through a die and then cooled directly after. These dies may be standardized for certain industries, but custom plastic extrusion can also be achieved through the production and use of custom dies.

There is some variation to this process for different types of extrusion. Single extrusion — as described above — is the most common for things like plastic sheeting, but certain products may require co-extrusion, where two or more polymers are pushed through the plastic extruder in tandem to produce different multilayered products. Tubing extrusion is also an option for relevant jobs, able to be performed on flexible polymers like polyurethane and low-density polyethylene (LDPE), semi-rigid materials like polypropylene and high-density polyethylene (HDPE), and rigid polymers including polycarbonate and polystyrene. Tubing extrusion is often performed with polyvinyl chloride (PVC) to manufacture tubing for use in construction and plumbing, among other industries.

Extruded Products

Plastic products of many kinds can be manufactured through the extrusion process. Thermoplastics are used to manufacture weatherstripping, window frames, and tubing of various plastic profiles. Polypropylene is used by the automotive industry to produce car bumpers, due to its characteristics that allow it to maintain impact resistance in cold weather. Acrylic is used to manufacture components for greenhouses and garages, because of its transparent and moisture-resistant properties.

Plastic extrusion is a manufacturing process whose successful completion is relied on by workers in all kinds of industries. At Plastic Extrusion Technologies, you can be confident you will receive a high-quality cost-effective product that meets your needs and allows you to — in turn — meet the needs of your customers.

Trust Plastic Extrusion Technologies for All of Your Plastic Extrusion Needs

Since 1997, Plastic Extrusion Technologies has provided extruded plastic tubing in various sizes. Our 45,000 square foot facility allows us to have the capacity to have plastic materials in stock and produce a large variety of plastics products for clients nation-wide. Offering high-quality, competitive pricing, and responsive service, Plastic Extrusion Technologies continually strives to be a leader in the custom plastic extrusion industry.

If you require plastic extruding services, contact Plastic Extrusion Technologies for more information. We would be happy to answer any questions you might have and meet your business’s needs. Contact us today!