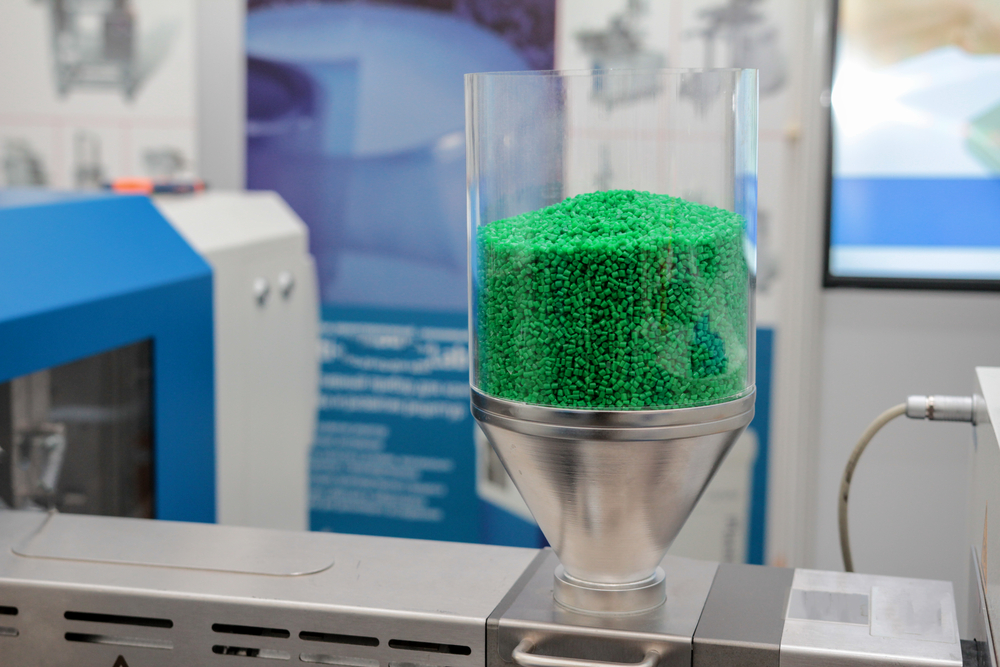

Plastic extrusion is a versatile manufacturing process that has significantly impacted various industries over the years. This involves pushing raw plastic material through a die to create specific shapes or profiles.

Plastic extrusion is used in a variety of industries and products including plumbing pipes and plastic tubing, 3D printing filaments, blown film extrusion, medical tubing, catheters, and automobile seals, gaskets, and interior trim pieces. It is also used to make plastic sheets and plastic film used in packaging. Its versatility allows a wide range of adaptation in many industries, making it a fundamental and highly utilized manufacturing process in modern production.

While plastic extrusion may seem simple, recent advancements have transformed it into a more sophisticated and efficient technology. The latest developments in plastic extrusion include multi-layer extrusion, foamed extrusion, precision extrusion, and innovative die designs. But, how are these innovations changing the future of manufacturing?

Multi-Layer Extrusion

Multi-layer extrusion, as the name suggests, is all about pushing multiple layers of different plastics or additives simultaneously through the extruder. This approach creates composite materials with unique properties, such as improved layer adhesion which is achieved through co-extrusion technology. This improves the bonding between layers, resulting in better barrier properties and product consistency.

In addition to better layer adhesion, multi-layer extrusion now allows for the inclusion of functional layers. These include UV barriers, oxygen scavengers, and antimicrobial additives which extend the shelf life and performance of products. With our energy-efficient multi-layer extrusion line, equipped with optimized cooling systems and precise controls, we have reduced operational costs and even environmental impact!

Multi-layer extrusion produces materials with superior mechanical, thermal, and barrier properties, making end products more high-performing. Being energy efficient and reducing plastic material waste, this advancement helps with cost savings for manufacturers. Plus, the ability to design materials with specific properties makes multi-layer extrusion suitable for various applications, from medical packaging to construction materials!

Foamed Plastic Extrusion

The foamed plastic extrusion process involves introducing gas or chemical foaming agents to create a cellular structure within plastic products. Recent progress in this field includes nano-cellular foaming. Nano-cellular foaming results in a material with excellent thermal insulation properties which is ideal for applications like energy-efficient building materials. This eco-friendly foaming agent aligns with the growing emphasis on sustainability in manufacturing.

Advanced foamed plastic extrusion techniques now produce products with controlled density variations, which is valuable for applications like automotive components and lightweight construction material. Controlled density distribution allows for the creation of lightweight yet strong components, reducing fuel consumption in the automotive and transportation sectors.

Precision Extrusion and Innovative Die Designs

Precision extrusion aims to achieve precise tolerances and high accuracy in product dimensions. Modern plastic extrusion lines are equipped with sensors and software, such as a breaker plate, that continuously monitor and adjust parameters like temperature, pressure, and extrusion rate, ensuring consistent product quality. Precision extrusion technologies enable the production of micro-sized and miniature plastic parts used in medical devices, electronics, and optics. With innovative die designs, such as spiral or adjustable dies, we have increased the flexibility of precision extrusion, allowing for quick adjustments and reduced setup times.

Real-time monitoring and control systems reduce variations in product quality, ensuring that each extruded piece meets stringent specifications. Precision extrusion opens doors to new applications in various industries, as it enables the creation of delicate and small-scale plastic components. Innovative die designs and precise control systems up the efficiency of the plastic extrusion process, reducing downtime and improving productivity.

What Can We Expect With These Latest Developments?

The collective advancements in plastic extrusion technology offer numerous benefits for manufacturers and end-users. Multi-layer and foamed plastic extrusion techniques enable us to create materials with superior mechanical, thermal, and barrier properties, resulting in higher-performing products. Precision extrusion technologies reduce plastic material waste and energy consumption, leading to cost savings for manufacturers. The ability to incorporate recycled material, use eco-friendly foaming agents, and optimize processes contributes to more sustainable and environmentally responsible manufacturing practices. These advancements open doors to a wider range of applications, from food packaging with extended shelf life to lightweight automotive components and medical devices with precise dimensions.

What Advancements Can We Expect in the Future?

In the rapidly evolving world of plastic extrusion services, we anticipate significant advancements. Smart manufacturing technologies are being used more than ever, leading to more automation and data-driven processes including real-time monitoring and control systems.

The integration of 3D printing and plastic extrusion holds great promise, opening up new avenues for custom manufacturing, rapid prototyping, and small-scale production. This has the potential to reshape traditional fabrication methods.

The development of biodegradable raw material is another exciting frontier. These eco-friendly materials are ready to start expanding the range of sustainable options in plastic extrusion that align with the growing emphasis on environmental responsibility.

Additionally, the aerospace and automotive industries are expected to benefit from the production of lightweight, high-performance materials through extrusion processes. These materials may contribute to fuel efficiency and sustainability!

In conclusion, advancements in the plastic extrusion process are reshaping the manufacturing landscape across various industries. Whether it’s multi-layer plastic extrusion that improves product performance or precision extrusion enabling high-precision components, these innovations are paving the way for a more sustainable, efficient, and versatile future. Staying informed about the latest developments is crucial for manufacturers and consumers alike, so we encourage you to visit us online and request a quote!