Since its invention, plastic has been hailed as one of the most useful materials known to man, and rightly so. Thanks to its natural characteristics of being cheaper and lighter than metal (while still boasting an impressive strength) plastic has become the construction material of choice in many applications.

Since its invention, plastic has been hailed as one of the most useful materials known to man, and rightly so. Thanks to its natural characteristics of being cheaper and lighter than metal (while still boasting an impressive strength) plastic has become the construction material of choice in many applications.

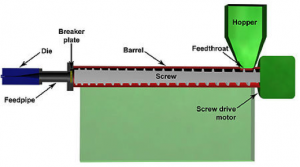

As might be expected, different applications require different types of plastics and in different shapes and sizes, which in turn requires specialized manufacturing processes. One such technique is called Plastic Extrusion. The plastic extruding process begins in the form of tiny plastic pellets (shown in the picture above). These premade plastic pellets are first shipped to the manufacturing facility, where additives such as colorants and UV inhibitors are then added as needed.

Before long, the mixture of pellets and additives will be melted inside the industrial equivalent of a gigantic melting pot, in which temperature is tightly regulated. Believe it or not, this “melting pot” is actually a tube! Known as the barrel, it allows the plastic pellets to be evenly dispersed by a huge rotating screw, which then transports the plastic through a heater, transforming the mixture from a solid into its molten state.

In most machines, one or more screens are present at the end of the barrel. The molten plastic is forced through these screens, service two purposes at once: the removal of contaminants & the provision of uniform resistance to keep pressure constant in the entire system. By the time the molten plastic passes through the screens, it is quite hot and ready to be shaped.

Shaping takes place by pushing the melted plastic through a die, directly after which the freshly molded profile is cooled. Generally speaking, the plastic extrusion process can be used to create basic shapes like plastic sheeting and piping, but it can also be used to create more advanced shapes using a custom die.

One of the largest benefits that plastic extrusion offers is continuous production. Provided with enough raw materials, machines used to extrude plastic don’t have to stop, because the entire process moves at the same pace without any stopping. Interestingly, this also allows the creation of extremely long pieces of plastic, something that other processes do with much less efficiency.

If you require plastic extruding services, contact Plastic Extrusion Technologies for more information. With over 100 years’ experience, we would be happy to answer any questions you might have and meet your business’s needs.